What is Sealant? What Functions Does It Serve in the Construction Industry?

Just as the selection of materials used in construction is important, so is the way these materials are brought together and the detailing solutions implemented. For structures exposed to external factors, waterproofing and sealing are critically important for ensuring long-term durability and user comfort. This is where sealants come into play.

The primary role of sealants is to prevent the ingress or egress of water, air, or other substances from or into the substrate to which they are applied.

What is a Sealant?

Sealants are generally elastic filling materials used to fill gaps between structural elements, bond different materials together, and ensure watertightness. They conform to the shape of the surface to which they are applied, completely filling any voids.

What Are the Primary Functions of Sealants in the Building and Construction Industry?

Sealants are typically used to close gaps between surfaces where materials like concrete and mortar cannot be applied effectively.

They serve three primary functions:

- Filling the gap between two or more components

- Providing a protective, impermeable barrier that prevents the passage of substances

- Maintaining their sealing properties throughout their expected service life under specified conditions and environments

Another key requirement for sealants is high flexibility, to tolerate movement between the different materials used. These movements may be caused by:

- Expansion or contraction due to thermal changes

- Dimensional variations resulting from changes in moisture content

- Deflections under load

- Wind pressure and similar factors.

What Are the Most Important Features to Consider When Choosing a Sealant?

Building materials differ in their coefficients of linear expansion. Due to differences in thermal expansion rates, the sealant selected must be suitable for the substrate materials being joined to ensure the desired performance and functionality. The sealant should have adequate adhesion properties and flexibility to tolerate any expected movement.

1. Product Identification:

The product packaging or technical datasheet will typically include terms such as “sealant” or “joint filler.” It should specify the intended purpose (e.g., filling, bonding, sealing) and what materials it is made from (e.g., silicone, polyurethane, acrylic).

2. Consistency:

High-viscosity sealants are preferred for vertical joints. Low-viscosity sealants are used in horizontal joints.

3. Hardness:

This defines the sealant’s resistance to deformation. It’s important to note that hardness is inversely proportional to flexibility—higher hardness usually means lower flexibility. Shore hardness is used to represent the hardness level of a sealant for specific applications. Among the Shore scales, Shore A is the most commonly used for sealants. Shore hardness is directly related to the material’s modulus of elasticity and thus its movement capability.

4. Weather Resistance:

High-performance sealants must withstand extreme temperatures, sunlight, and moisture while remaining flexible and performing as expected.

5. Durability:

Over its service life, a sealant is exposed to various environmental factors and stresses that may cause degradation on the surface or within the material. These factors can lead to discoloration, loss of gloss, shrinkage, and cracking. The primary factor in a sealant’s durability is its resistance to deterioration caused by environmental conditions such as UV exposure and temperature fluctuations. Sealants are materials that, under ideal conditions, demonstrate long-lasting durability. However, in some applications—especially if misapplied or incompatible with the substrate—these conditions may not be met.

6. Modulus of Elasticity:

This defines the force applied per unit area under stress for the sealant. Since a sealant’s primary function is to adhere to substrates, the forces created by joint expansion or contraction are transmitted through the sealant to the substrate. Therefore, knowing both the modulus of the sealant and the strength of the substrate is important.

Generally, low-modulus sealants offer greater movement capability and are used for delicate surfaces, while high-modulus sealants are suitable for static or non-moving joints.

7. Adhesion Properties:

Sealants exhibit good adhesion to various surfaces (such as concrete, wood, metal, ceramic, etc.). This allows them to fill gaps effectively and ensure watertightness.

8. Staining:

Sealant components can stain certain substrates, especially porous ones like natural stone. It is recommended to perform a test before application.

9. VOC Content:

Volatile Organic Compounds (VOCs) found in sealants can cause respiratory irritation. While many manufacturers have developed low-VOC sealants, this is not the case for all products, and it is always best to check the VOC content before use.

10. Cost:

Sealant prices can vary greatly depending on performance levels and intended applications. It’s important to remember that replacing failed sealants is often more expensive than selecting the correct sealant from the beginning. To avoid future expenses, sealants should be matched carefully with the performance requirements of the application.

11. Product Applications:

Sealants are commonly used for purposes such as joint filling, sealing, and bonding. For more detailed information;

Sealants: https://www.fixaco.uk/products/sealants/

Technical Adhesives: https://www.fixaco.uk/products/technical-adhesives/

12. Product Packaging:

Sealants are typically sold in cartridges, tubes, or buckets. The packaging usually includes the product name, properties, and application instructions.

Why Are Auxiliary Materials Used in Sealant Applications?

Before applying sealant, round-profile polyethylene foam backer rods are placed beneath the joints. This serves two main purposes:

- To control the depth of the sealant within the joint

- To provide support for the sealant in horizontal joints

The sealant should not adhere to the polyethylene foam backer rods. The selection of joint backer rods depends on the type of sealant used and the specific site conditions.

Why is Sealant Application Depth Important?

To minimise the stresses caused by deformation on the sealant surface, the depth of the sealant should always be less than its width.

The following guidelines are used in sealant applications:

- The minimum dimensions are 5 x 5 mm,

- For widths between 5 and 12 mm, the depth should be slightly less than the width,

- For widths between 12 and 25 mm, the depth should be 8 to 12 mm,

- For widths greater than 25 mm, the depth should be 12 to 18 mm depending on the chemical type of the joint, and preferably half the width.

The depth of joints is usually adjusted using a polyethylene backer rod, which is inserted and compressed between the lips of the joint.

What is the Difference Between Adhesives and Sealants?

Sealants are designed to fill and seal joints, and the selected material must be capable of movement and adhesion to the substrate. Depending on the materials being joined and the structure’s location, they must also be flexible enough to accommodate effects from heating, cooling, and vibrations. Sealants allow for expansion and contraction, helping to prevent structural damage and mold formation, while also serving as a barrier against air and water.

Sealants are classified according to the chemistry they use. Each formulation has different characteristics in terms of weather resistance, application temperature range, movement capability, service life, odor during curing, curing time, potential for bubbling during cure, need for priming, stain resistance, paintability, application ease, cleanability, water resistance, adhesion to different substrates, and UV resistance.

Some materials may serve both as sealants and adhesives, performing dual functions of sealing and bonding between surfaces.

Adhesives, on the other hand, some materials are specifically designed to bond surfaces together and hold substrates in place—often used as alternatives to mechanical fasteners such as screws and nails.

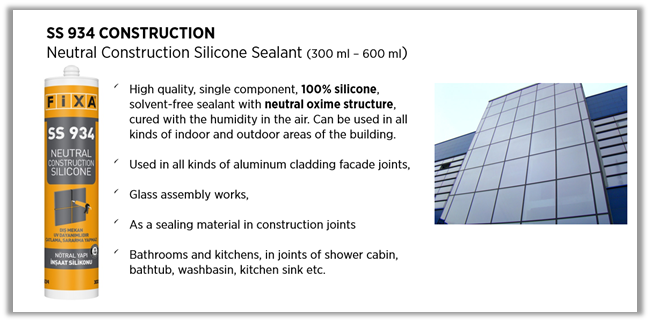

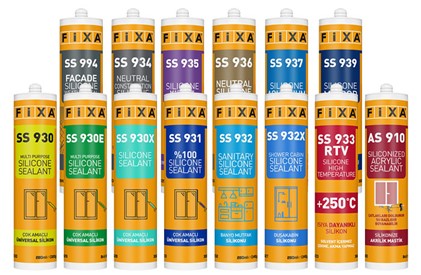

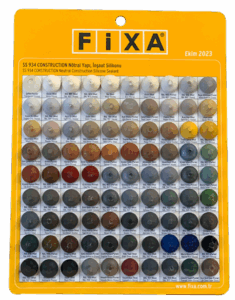

Advantages of FİXA Sealants

- High Quality: FİXA sealants are manufactured using high-quality raw materials.

- Wide Product Range: Offering various sealant solutions tailored to different needs.

- Easy Application: User-friendly and practical to apply.

- Durability: Deliver long-lasting and reliable results.

Sealants hold a significant place in the construction industry. Choosing and applying the right sealant enhances the durability and lifespan of structures.

FİXA provides a wide range of products to meet waterproofing and sealing needs. With both sealants and joint fillers, it offers solutions suitable for different areas of a structure.

Sealants and Joint Fillers: Indispensable Elements of Modern Structures

With the right product selection and application, structures can maintain their durability and aesthetic appeal for many years. With FİXA’s high-quality products and expertise, you can find the most suitable solutions for your buildings.

In the field of technical adhesives and sealing products, the use of joint fillers serves several purposes:

Surface Protection and Aesthetic Appearance:

Joint fillers fill the gaps between surface coverings such as ceramic, tile, and marble, protecting the surfaces while also enhancing their aesthetic appeal. Especially in areas exposed to water and humidity, joint fillers help prolong the life of coverings by preventing water absorption.

Waterproofing and Sealing:

In wet areas like bathrooms, kitchens, and toilets, joint fillers are essential to prevent water from damaging building elements. When properly selected and applied, they prevent water from penetrating through the joints and reaching the underlying structural layers, thus ensuring effective waterproofing.

Hygiene and Cleanliness:

Joint gaps can serve as breeding grounds for dirt and bacteria. Joint fillers eliminate these gaps, reducing dirt accumulation and making cleaning easier. Their use is especially crucial in hygiene-sensitive areas such as food processing facilities and healthcare institutions.

Durability and Longevity:

High-quality joint fillers are resistant to abrasion, impacts, and chemicals. As a result, they retain their properties for many years and contribute to the structural durability of buildings.

Ease of Application:

Today, there are many types of joint fillers available. Most of these are easy to apply and cure quickly, becoming ready for use in a short time.

In the field of technical adhesives and sealing products, the use of joint fillers offers numerous advantages such as structural protection, aesthetic enhancement, waterproofing, hygiene, durability, and ease of application. For this reason, joint fillers hold an indispensable place in the construction industry.

For detailed information about Sealants and Technical Adhesives, contact us via our website www.fixaco.uk by phone on +44 (0) 208 176 0680 or email us at info@fixaco.uk

FAQ

1. What is sealant and where is it used?

Sealant is a flexible and waterproof filling material used in construction. Its main function is to fill gaps where two building elements meet and to form a barrier. It is commonly used in joints, cracks, and connection points—for example, around windows and doors, in bathrooms and kitchens, on exterior claddings, and in waterproofing applications.

2. What is grout and how does it differ from sealant?

Grout is a material used to fill the gaps between tiles, ceramics, or stones. Unlike sealants, grout is usually harder and more durable. Sealants are more flexible and are preferred for joints that may move or shift.

3. What types of sealants are there and where are they used?

Main types of sealants include:

- Silicone sealant: Water-resistant; used in moist environments like bathrooms and kitchens.

- Polyurethane sealant: Flexible and durable; used in exterior facades and floor joints.

- Acrylic sealant: Paintable; used indoors for cracks and joint filling.

- Hybrid sealant: Combines properties of silicone and polyurethane; suitable for a wide range of applications.

4. What should be considered when choosing a sealant?

Pay attention to the application area’s characteristics, flexibility of the material, resistance to water and weather, color compatibility, and ease of application.

5. How is sealant applied?

The surface should be clean and dry. The sealant is applied to the joints using a gun or spatula. Excess material is cleaned off and left to dry.

6. How long does sealant take to dry?

Drying time depends on the type of material and weather conditions. Typically, it dries fully within 24 to 48 hours.

7. How do you clean moldy sealant?

Mouldy areas can be cleaned with anti-mould sprays or bleach. If necessary, the old sealant or grout can be removed and reapplied.

8. Why does sealant crack or degrade?

Cracking or degradation can occur due to improper application, poor material choice, excessive moisture, temperature fluctuations, or movement of the surface.

9. What is the difference between paintable and non-paintable sealants?

Paintable sealants have a special formulation that allows them to be painted over. Acrylic sealants are usually paintable, while silicone sealants are not.

10. What should I consider when purchasing sealant?

Check the expiration date, suitability for the intended application, brand, and quality. Choosing a trusted brand helps ensure long-lasting and durable results.

Share!

Other Blog Posts