What is Anchoring in Construction? Which Construction Chemicals Are Used in Anchor Applications?

In the construction industry, anchoring systems are critical applications used to connect structural elements, strengthen load-bearing systems and enhance resistance to external factors. They play a key role in ensuring safety and stability in foundations, bridge piers, tunnels and high-rise buildings. These systems fall into two main categories—mechanical and chemical anchoring—and are implemented using steel rods, anchors or special adhesives.

In modern anchoring applications, high-performance construction chemicals play a crucial role. Epoxy-based resins, cement and epoxy-based grout mortars, chemical anchors and polymer-reinforced binders ensure that anchoring systems are long-lasting and possess high strength. Products such as REPOX 302 Flowable Epoxy Anchoring and Assembly Mortar, REPOX 340 Polyester Chemical Anchor and REPAİRGROUT GP F65, REPAİRGROUT GP-S F65, REPAİRGROUT GP F50, REPAİRGROUT GP F40—all shrinkage-free flowable grout and anchoring mortars—offer effective solutions for anchoring systems that demand high strength.

In this article, we will explore in detail the functions of anchoring systems, the construction chemicals used and how these chemicals impact performance. We will also examine how anchoring technologies are applied across various sectors, from tunnels to bridge construction and highlight the innovative solutions provided by FİXA.

What is Anchoring and Why is it Used in Construction?

Anchoring is a critical construction practice that ensures the stabilisation of structural elements, enables safe load transfer and maintains structural integrity. Anchor systems are used to enhance structural safety and to prevent deformations caused by vibrations and external forces. These systems have a wide range of applications in areas requiring high strength. In civil engineering, anchoring solutions are commonly used in tunnel structures, bridges, building foundations and ground improvement projects. FİXA’s chemical anchors and grout mortars are examples of the high-performance construction chemicals that are used effectively in such applications.

Definition and Primary Function of Anchoring

Anchoring is defined as a connection system used to securely connect concrete, steel or other structural elements. In the construction industry, they are applied to increase load-bearing capacity, connect structural components and enhance resistance against external influences. Anchor systems, particularly used for ground stabilization, reinforcement of load-bearing elements and extending the service life of structures, are applied to surfaces using mechanical or chemical components.

Applications of Anchoring in Construction

Anchoring applications are a fastening method used to ensure safe load transfer in various structural systems. They are commonly used in tunnels, bridge piers, foundations of high-rise buildings and structures exposed to wind and seismic loads. Additionally, anchoring is employed in areas such as rock stabilisation, equipment installation in industrial facilities and strengthening of historical structures.

Differences Between Mechanical and Chemical Anchoring

Anchoring systems are divided into two main categories: mechanical and chemical. Mechanical anchors attach to the surface using components such as steel anchors, expanding arms, and nuts. These systems are typically used in projects that require the support of heavy loads and in applications where installation is done on pre-drilled surfaces.

Chemical anchors, on the other hand, create a chemical bond with the surface using epoxy, polyester, or vinyl ester-based resins. These systems are especially preferred in high-strength projects because they offer superior adhesion and long-term durability. REPOX 340 Polyester Chemical Anchoring Adhesive is standout product in this category, known for their high tensile strength and fast curing properties.

Construction Chemicals Used in Anchoring Systems

Construction chemicals used in anchoring systems are materials that enhance bonding strength, reinforce load transfer, and support the longevity of structural components. Chemical anchoring materials provide strong adhesion to construction surfaces such as high-strength concrete, steel, and stone, thereby increasing the safety of the structure. Epoxy, polyester, and vinyl ester resins, cement-based grout mortars, and polymer-based binders are the main construction chemicals that offer high-strength anchoring solutions in modern construction projects. FİXA’s REPOX series of chemical anchors and REPAİRGROUT series of grouts provide reliable and durable solutions in these systems.

Epoxy and Polyester Chemical Anchor Systems

Epoxy and polyester chemical anchor systems provide strong adhesion on surfaces such as concrete, stone, metal, and other construction materials, enhancing the long-term durability of anchoring components.

Epoxy-based chemical anchors offer high chemical resistance and exceptional mechanical strength, making them ideal for safely securing heavy loads. Polyester-based systems, on the other hand, provide faster curing times and cost-effective solutions, making them suitable for applications requiring moderate strength.

- REPOX 302 is an epoxy-based chemical anchor developed for high-strength anchoring applications. Its low-viscosity formula allows it to penetrate narrow holes easily, delivering superior adhesion strength.

- REPOX 340 is a polyester chemical anchor used in medium and light-load anchoring applications. Thanks to its fast curing feature, it offers an advantage in projects requiring rapid installation.

Epoxy and polyester-based chemical anchors are widely used—from tunnels to high-rise buildings—due to their high temperature resistance, strong bonding on moist surfaces, and long-lasting performance.

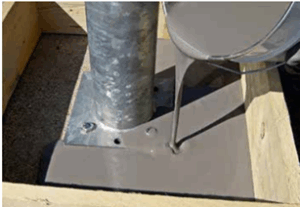

Cement-Based Grout and Anchoring Mortars

Cement-based grout and anchoring mortars are high-strength materials used to secure anchor rods, machine foundations, and structural elements. These mortars provide excellent compressive strength and ensure homogeneous load distribution within anchoring systems, thereby preventing the formation of cracks.

- REPAİRGROUT GP F65 is a non-shrink, highly flowable grout mortar. It is suitable for anchoring machine bases, columns, and heavy industrial equipment.

- REPAİRGROUT GP-S F65 is a sulfate-resistant version, ideal for use in damp ground and environments exposed to aggressive chemicals. Its high strength offers a long-lasting anchoring solution.

Cement-based anchoring mortars resist impact and loads, contributing to the long-term safety and durability of structures. Their high flowability allows them to fill voids and form a strong bond with the surface.

Polymer and Fiber Reinforced Chemical Binders

Polymer and fiber reinforced chemical binders are specially formulated construction chemicals used in anchoring applications to enhance crack-bridging, flexibility, and mechanical strength. Epoxy and polyurethane-based polymer systems provide long-term performance in anchoring systems through their high flexibility and vibration-absorbing properties.

- Fiber-reinforced chemical binders create a strong bond with steel reinforcements and anchor elements, increasing resistance to vibration.

- Polymer-reinforced epoxy systems offer high chemical resistance and flexibility, delivering extra protection against sudden load changes.

These chemical binders play a critical role in reinforcement solutions used in high-rise buildings, bridge piers, and tunnels. Thanks to their high impact absorption capabilities, they help minimise damage caused by vibrations or seismic activity, thereby enhancing the safety of structures.

The Impact of Construction Chemicals on Anchoring System Performance

The durability and safety of anchoring systems depend on the performance of construction chemicals under environmental conditions and mechanical loads. Epoxy and cement-based grout mortars and chemical binders not only increase the load-bearing capacity of anchor elements but also determine their resistance to heat, chemical exposure, and mechanical stress. Conditions such as high temperature, humidity, and vibration directly affect the performance of anchoring resins and mortars. Therefore, selecting the right construction chemicals in building projects is crucial for both cost efficiency and structural safety.

Performance of Epoxy-Based Anchors Under High Temperatures

Epoxy-based anchoring systems respond differently to changes in high temperature. Epoxy resins typically risk losing mechanical strength under elevated temperatures, but this can be mitigated with specialised formulations. In tunnel boring projects, maintaining the thermal resistance of anchoring materials is particularly important.

- Epoxy-based chemical anchors may lose bond strength when exposed to high temperatures; however, heat-resistant formulations help minimize this effect.

- REPOX 302 epoxy-based chemical anchor performs strongly in systems requiring heat resistance, minimising bond loss caused by temperature fluctuations.

The performance of epoxy-based anchoring systems under high temperatures varies depending on the binder composition, surface preparation, and environmental conditions.

Adhesion, Strength, and Tensile Resistance of Anchoring Resins

The performance of anchoring resins is critically evaluated in terms of surface adhesion, load-bearing capacity, and tensile strength. Epoxy-based resins offer high bonding strength, while polyester-based chemical anchors are advantageous for their rapid curing times.

- Epoxy-based chemical anchors provide high adhesion to concrete and stone surfaces, offering exceptional resistance to tensile loads.

- Polyester-based resins offer medium load-bearing capacity and are preferred for projects requiring quick curing.

- REPOX 340, a polyester-based chemical anchor, delivers a durable solution in anchoring applications with its strong adhesion, while REPOX 302, an epoxy-based product, ensures long-term

stability in high-strength applications.

In terms of tensile strength, epoxy-based resins provide the highest resistance, whereas polyester and vinyl ester-based chemicals offer more economical and quicker solutions for specific applications.

Comparison of Anchoring Mortars in Terms of Chemical and Mechanical Resistance

Cement-based grout and anchoring mortars offer different advantages in terms of chemical and mechanical resistance. Especially under aggressive environmental conditions, products that resist sulfates, chloride ions, and other chemicals play a critical role in ensuring long-term structural safety.

• Sulfate-resistant grout mortars provide extra durability in areas exposed to sulfates and corrosive salts.

• REPAİRGROUT GP F65, with its non-shrink feature, enhances mechanical resistance in anchoring systems, while its sulfate-resistant version, GP-S F65, offers additional protection against sulfates.

Grout mortars with enhanced chemical resistance maintain the stability of anchoring elements by delivering long-term performance in moist and aggressive environments.

Sectoral Applications and the Future of Anchoring Chemicals

Anchoring systems play a significant role not only in traditional building projects but also in large-scale infrastructure and industrial applications. In tunnel boring, high-rise buildings, bridges, and other engineering projects, epoxy and cement-based anchoring systems increase load-bearing capacity and improve structural durability. With advancing technology, next-generation materials that boost the performance of chemical binders and grout mortars are becoming increasingly common in the industry. FiXA, through its innovative anchoring solutions, offers reliable and long-lasting alternatives for applications that require high strength.

Use of Epoxy and Cement Grout Anchors in Tunnel Boring Projects

Tunnel boring projects require the most robust anchoring solutions due to high pressure and challenging ground conditions. In such projects, chemical resins and cement grout anchoring systems are used to minimise rock instability and the risk of tunnel collapse.

- Epoxy-based chemical anchors, with their fast curing time and high tensile strength, provide effective solutions in tunnel projects exposed to dynamic loads.

- Cement-based grout mortars support tunnel walls and rock anchors with their high compressive strength, offering long-term stability against geological movements.

- REPOX 302 epoxy anchoring mortar provides strong adhesion in tunnel boring applications, enhancing structural resistance to seismic effects.

- REPAİRGROUT GP F65 is a high-strength grout mortar used to reinforce concrete surfaces.

These types of chemical anchoring solutions enhance safety and support structural stability in tunnel boring applications.

Cement and Epoxy Anchoring Systems in High-Rise Buildings and Bridges

High-rise buildings and bridges are among the most critical engineering projects where anchoring systems play a vital role. Wind loads, seismic movements, and heavy structural components require anchoring systems with superior performance.

- Epoxy-based anchoring systems enhance seismic safety by ensuring strong bonding of steel reinforcements to concrete surfaces.

- Cement-based grout mortars are used in high compressive strength anchoring applications to ensure the stability of structural elements.

- REPAİRGROUT GP-S F65 is a sulfate-resistant grout mortar used in bridge foundations, offering additional protection against corrosion.

These chemical solutions improve safety in tall structures and bridges by creating long-lasting and durable anchoring systems.

Next-Generation Materials in Anchoring Technologies and FİXA’s Innovative Solutions

With the advancement of the construction industry, new-generation materials and more efficient solutions have been developed in anchoring technologies. Polymer-based binders, nano-enhanced resins, and environmentally friendly anchoring chemicals offer high performance while reducing the carbon footprint.

- Polymer-reinforced chemical binders offer more flexible and earthquake-resistant solutions with improved elasticity.

- Epoxy and polyurethane-based resins provide excellent adhesion and faster curing times, accelerating workflow.

- FİXA’s innovative anchoring solutions deliver sustainable and long-lasting alternatives to the construction industry through advanced chemical formulations.

Next-generation anchoring technologies provide more durable, faster-applying, and environmentally resistant solutions, increasing the safety of construction projects. FİXA’s chemical anchors and grout mortars contribute to the development of the industry by offering reliable and high-performance anchoring systems for future construction projects.

In this context, FİXA’s innovative chemical anchoring solutions play a critical role in construction projects by delivering reliable and long-lasting structural support across various sectors. In the construction technologies of the future, FixXA continues to be a pioneer with strong anchoring solutions and construction chemicals.

For detailed information, contact us via our website www.fixaco.uk by phone on +44 (0) 208 176 0680 or email us at info@fixaco.uk

Sources:

- Tension and Shear Anchorage Systems for Limestone Structures | isprsarchives.org

- Design and Evaluation of a New Bond-Type Anchorage System | researchgate.net

- 1-s2.0-S2214509523005843-main | sciencedirect.com

- Polymers-16-01960 | mdpi.com

- Chemical Anchoring Systems and Performance Evaluation in Construction | sciencedirect.com

- Epoxy and Grout Anchorage Applications in Mining and Tunneling | e3s-conferences.org

- Cement and Epoxy-Based Anchorage Systems in High-Rise Buildings and Bridges | sciencedirect.com

- New Generation Materials and Advances in Anchorage Technologies | mdpi.com

- fixa.com.tr

Share!

Other Blog Posts