The Critical Role of Adhesives and Sealants in Modern Engineering and Design

Adhesives and sealants play an indispensable role in contemporary manufacturing, construction and design industries. As the demand for lightweight materials, environmental sustainability, and efficient assembly processes continues to grow, the reliance on advanced bonding and sealing technologies has become more prominent. These substances are no longer secondary materials but are central to the structural integrity, performance and longevity of countless products and infrastructures.

Unlike traditional mechanical fastening methods, adhesives and sealants offer the advantage of uniform stress distribution, material compatibility, and aesthetic refinement. Their applications range from microelectronics and automotive assembly to building façades and aerospace engineering.

Innovations in chemical formulation now allow for custom properties—such as flexibility, thermal resistance, and waterproofing—tailored to specific industrial needs. As a result, adhesives and sealants are redefining the standards of safety, durability, and efficiency across sectors.

Transform Your Projects with FX1 FIX&GO: The Ultimate Adhesive for Unmatched Strength

Whether you’re tackling a home improvement project, an industrial application or a creative DIY endeavour, using the right adhesive makes all the difference.

FX1 FIX&GO is a high-performance bonding solution designed to deliver durability, flexibility, and superior adhesion—making it the perfect choice for professionals and enthusiasts alike.

Why Choose FX1 FIX&GO?

Finding a reliable adhesive that works across various surfaces can be a challenge. FX1 FIX&GO stands out with its advanced formulation, ensuring strong and long-lasting bonds on a range of materials, including ceramics, wood, metal, and concrete. Its weather-resistant properties make it suitable for both indoor and outdoor use, offering protection against moisture and temperature changes.

Key Benefits of FX1 FIX&GO

Key Benefits of FX1 FIX&GO

Exceptional Bonding Strength – Designed to hold even the most demanding materials together with ease.

Versatile Application – Works effectively on ceramics, wood, metal, concrete, and more.

Weather & Moisture Resistance – Ideal for outdoor and humid environments, ensuring longevity.

Easy-to-Use Formula – Designed for effortless application with precise control, reducing waste.

Durability You Can Trust – Provides a long-lasting hold, resisting wear and environmental factors.

How to Use FX1 FIX&GO Effectively

Applying FX1 FIX&GO is a straightforward process that ensures optimal results:

- Prepare the Surface – Ensure surfaces are clean, dry, and free from dust or debris.

- Apply the Adhesive – Spread an even layer of FX1 FIX&GO on one of the surfaces to be bonded.

- Press Firmly – Bring the materials together and apply firm pressure for secure adhesion.

- Allow for Proper Curing – Give the adhesive sufficient time to set, ensuring maximum strength.

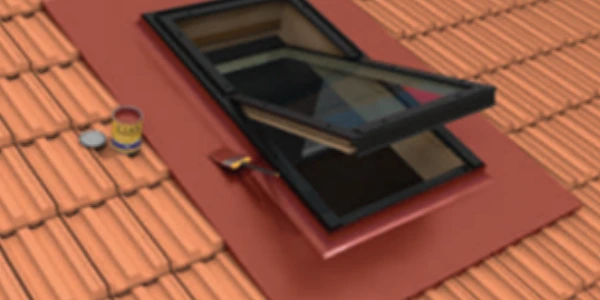

Ideal for a Wide Range of Applications

From home renovations to industrial repairs, FX1 FIX&GO is trusted by professionals in construction, manufacturing and design. Whether you’re fixing broken tiles, securing heavy materials, or creating innovative projects, this adhesive offers the strength and versatility you need to get the job done right.

Upgrade your adhesive game with FX1 FIX&GO—because strong bonds build lasting projects!

Are you ready to experience the power of FX1 FIX&GO? Share your latest project using this incredible adhesive and let us know how it transformed your work!

If you have any queries about our product or any of our technical adhesives contact us on +44 (0) 208 176 0680 or email us at info@fixaco.uk

FAQ

- What distinguishes adhesives from sealants in industrial applications?

Adhesives are primarily used to bond two surfaces together by forming a solid material between them, whereas sealants are designed to fill gaps and prevent the passage of fluids or gases, often providing elasticity and insulation as well. - Why are adhesives and sealants increasingly preferred over mechanical fasteners?

They enable lighter constructions, reduce material fatigue, distribute stress more evenly and allow for more streamlined, aesthetically pleasing designs without compromising structural integrity. - What industries benefit most from adhesive and sealant technologies?

Key sectors include automotive, aerospace, electronics, construction, medical devices, packaging and renewable energy—each leveraging these materials for specific performance requirements. - How do environmental conditions impact adhesive and sealant performance?

Factors such as temperature, humidity, UV exposure and chemical contact can influence curing time, adhesion strength and longevity. High-performance formulations are developed to withstand such variables. - Are there sustainable or eco-friendly options available?

Yes. The industry is rapidly innovating with low-VOC (volatile organic compound) adhesives, bio-based resins and recyclable formulations to reduce environmental impact. - How is bond strength measured, and why is it critical?

Bond strength is typically measured in terms of tensile, shear and peel strength. It determines the adhesive’s capability to hold substrates together under various mechanical forces and environmental stresses. - Can adhesives and sealants be used on dissimilar materials?

Absolutely. One of their key advantages is the ability to join materials with different physical and chemical properties, such as metals to plastics or composites to ceramics. - What are the key considerations when selecting an adhesive or sealant?

Material compatibility, mechanical stress, curing time, environmental exposure, application method, and regulatory compliance are all essential factors in product selection. - How does curing time affect the production process?

Shorter curing times can increase production efficiency but may require specific environmental controls. Conversely, longer curing can enhance strength and resistance but may slow down throughput. - Are there any limitations to using adhesives and sealants?

While highly versatile, they may be sensitive to surface preparation, temperature ranges, and aging. Proper handling, application, and material pairing are crucial to ensuring performance reliability.

Share!

Other Blog Posts