POLYMERA MS 960 WINDSHIELD Automotive Glass Adhesive: Strong and Durable Bonds

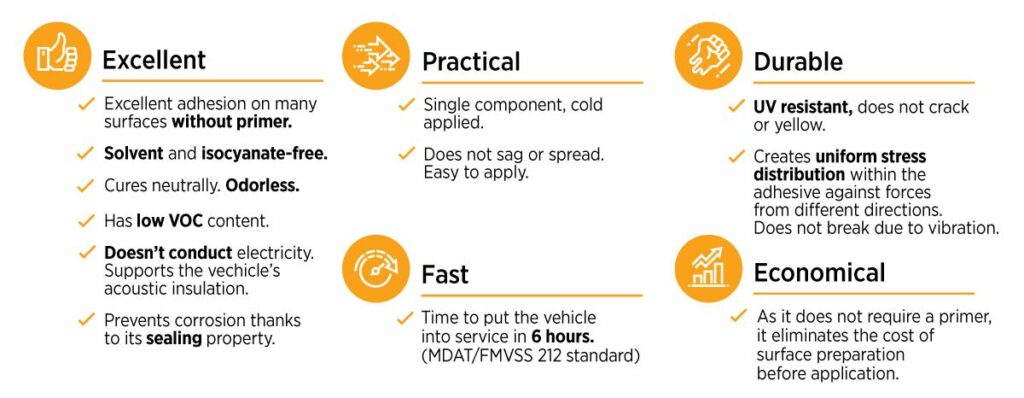

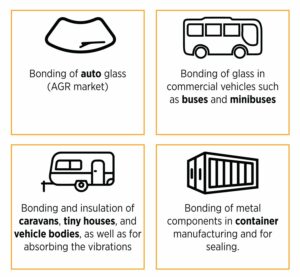

POLYMERA MS 960 WINDSHIELD automotive glass adhesive is a reliable solution for vehicle glass assembly, offering strong adhesion, high elasticity, and long-lasting durability. It provides superior resistance to vibrations, temperature changes, and external factors, ensuring the glass adheres securely to the vehicle body. Its solvent- and isocyanate-free formula offers safe application and serves as an environmentally friendly alternative to traditional adheasives. Its UV resistance and weatherproof structure maintain bond stability for many years.

Achieve maximum safety and performance in automotive glass bonding with Polymera MS 960!

What is Automotive Glass Adhesive?

Automotive glass adhesive is a special type of adhesive used to securely and durably mount vehicle glass. Vehicles are constantly exposed to vibrations, temperature fluctuations, and external conditions, requiring the bond between glass and body to be flexible, strong, and long-lasting.

Incorrect adhesive choice or faulty application can lead to glass loosening, leakage issues and even safety hazards. Correct adhesive choice prevents glass movement, stops water, dust, and air leaks, enhancing the comfort inside the vehicle.

Especially in modern vehicles using lightweight and durable materials, the adhesive must be high-strength and flexible. Wıth vehicles subjected to vibrations and shocks over time the adhesive must maintain its bonding strength and elasticity under these dynamic conditions.

Advanced automotive glass adhesives like Polymera MS 960 are specially formulated to meet these requirements with vibration absorption and long-lasting durability.

![]()

What is the Difference Between Traditional Automotive Glass Adhesives and MS Polymer-Based Adhesives?

Traditional automotive glass adhesives are generally polyurethane or solvent based and may require a primer during application. Due to their chemical content, they can pose certain health risks. Solvent-based adhesives often emit strong odors during curing and require ventilation in the working environment. Additionally, adhesives containing solvents may experience volume loss over time, weakening the bond between the glass and the vehicle body.

On the other hand, MS Polymer-based automotive glass adhesives are solvent- and isocyanate-free, environmentally friendly, and less harmful to human health. These adhesives have high elasticity and adhere excellently to surfaces, providing both a strong and flexible bond.

Polymera MS 960, as an MS Polymer-based automotive glass adhesive, is safer compared to solvent-based adhesives and offers superior resistance to UV rays and temperature changes.

What to Consider When Choosing Automotive Glass Adhesive?

Choosing the right automotive glass adhesive is critical for vehicle safety and long-term durability. Using the wrong adhesive can lead to loosening of the glass over time, loss of sealing, and even serious safety hazards. Therefore, the automotive glass adhesive must have strong adhesion, high resistance to temperature and UV rays, and a formula that is safe for human health.

For these reasons, the product’s technical specifications, ease of use, and resistance to environmental factors must be carefully considered when selecting automotive glass adhesives.

Polymera MS 960 is specially developed to meet these criteria. With its MS Polymer-based structure, it offers high elasticity, excellent resistance to UV rays and temperature fluctuations, ensures a durable bond, guaranteeing the secure installation of vehicle glass.

Why is Strong Adhesion Important in Automotive Glass Adhesives?

An automotive glass adhesive not only secures the vehicle’s glass to the body but also enhances resistance to vibrations, impacts, and weather conditions. While the vehicle is in motion, the glass is continuously exposed to pressure and vibrations, making it critical for the adhesive to form a flexible yet strong bond.

If the adhesive is not strong enough, over time the glass may loosen, the seal may fail, or cracks may develop. Automotive glass adhesives with high modulus properties, like Polymera MS 960, tolerate movements at the bonding points and maintain sealing performance for a long time.

Strong adhesion not only improves mechanical durability but also enhances insulation between the glass and the vehicle body. It prevents issues such as water leakage, dust ingress, and wind noise, thereby increasing driving comfort.

While traditional adhesives may experience volume loss over time, Polymera MS 960 maintains its volume and adhesive strength after curing, preserving long-term durability.

Polymera MS 960 automotive glass adhesive boasts a high modulus value. This enables it to tolerate movements at bonding points and keep the glass securely fixed while the vehicle is in motion. Traditional adhesives may harden over time, causing cracking or loosening, whereas Polymera MS 960 maintains its elasticity and shows excellent resistance to external factors. Its durability against vibrations and shocks offers long-term usage benefits and lasting sealing ability.

Sealing ability is one of the most important performance criteria for automotive glass adhesives. Polymera MS 960 prevents the ingress of water, wind, and dust, protecting the vehicle interior. Once fully cured, it resists adverse effects of moisture, temperature fluctuations, or chemicals on the adhesive. Thus, the glass stays firmly in place without deformation. These features make Polymera MS 960 not only provide strong adhesion but also enhance comfort and safety inside the vehicle.

Why Are UV Resistance and Temperature Durability Critical Factors?

Vehicle glass is exposed directly to sunlight and outdoor weather conditions. If an automotive glass adhesive is not resistant to UV rays, it can deteriorate over time, causing yellowing, drying, and cracking.

Adhesives with poor UV resistance may harden and lose elasticity due to sun exposure, potentially causing the glass to loosen or the adhesive to become brittle.

Polymera MS 960 offers long-term stability with its UV-resistant formula, preventing yellowing and loss of elasticity.

Temperature fluctuations also play a critical role in the performance of automotive glass adhesives. Interior vehicle temperatures can exceed 60°C in summer and drop to -30°C in winter.

Adhesives that cannot withstand these temperature changes may sag in excessive heat or become brittle in extreme cold. Polymera MS 960 maintains its elasticity and adhesion strength between -40°C and +80°C, ensuring a secure bond under all weather conditions.

How to Use Automotive Glass Adhesive?

Proper application of automotive glass adhesive is critical for securely fixing the glass. Incorrect application can weaken the bond over time, causing the glass to loosen and seal failure. Surface preparation, correct equipment use, and adequate curing time are essential factors. Polymera MS 960 is a single-component adhesive that offers easy application.

First, the surface must be properly cleaned and prepared. Dirt, oil, dust, and old adhesive residues must be removed to ensure full adhesion of the new adhesive. Previously applied and cured adhesives must be mechanically removed entirely; new adhesive should not be applied over old residue.

Although Polymera MS 960 generally does not require a primer, one may be applied depending on surface conditions. The adhesive should be evenly applied to the surface with a sausage gun, and the glass firmly positioned to the body. During the curing period, the vehicle must not be moved, and sufficient time should be allowed to ensure full bonding.

Application of Polymera MS 960 is an easy and effective process when using the right equipment and methods. The sausage gun allows for smooth, controlled application compared to manual methods. The adhesive should be dispensed evenly and ensure full contact between the glass and the surface. Incorrect application can reduce adhesion performance and cause sealing issues.

After application, any adhesive spilled on unwanted areas must be cleaned within 5 minutes using solvent or alcohol. After this time, removing cured adhesive is only possible mechanically. The full bonding process requires the vehicle to remain stationary. Polymera MS 960 fully cures in approximately 24 hours, with a minimum vehicle usage time of about 6 hours. During this period, preventing vibrations is crucial for optimal adhesive bonding.

Application steps can be found in the Polymera MS 960 Automotive Glass Adhesive product brochure available on our website.

The Right Choice for Safe and Durable Automotive Glass Installation!

Secure your vehicle’s glass safely with Polymera MS 960! Thanks to its high adhesion strength, superior flexibility and resistance to temperature fluctations, Polymera MS960 ensures a long-lasting, reliable bond providing maximum protection against vibrations, temperature changes, and external factors. Explore it now and discover the best solution for your vehicle!

Experience the durable and professional solutions offered by Polymera MS 960! You can also check out our other MS Polymer-based adhesive products.

For detailed information, contact us by phone on +44 (0) 208 176 0680 or email us at info@fixaco.uk

Share!

Other Blog Posts